Pioneering the next generation of towing innovation

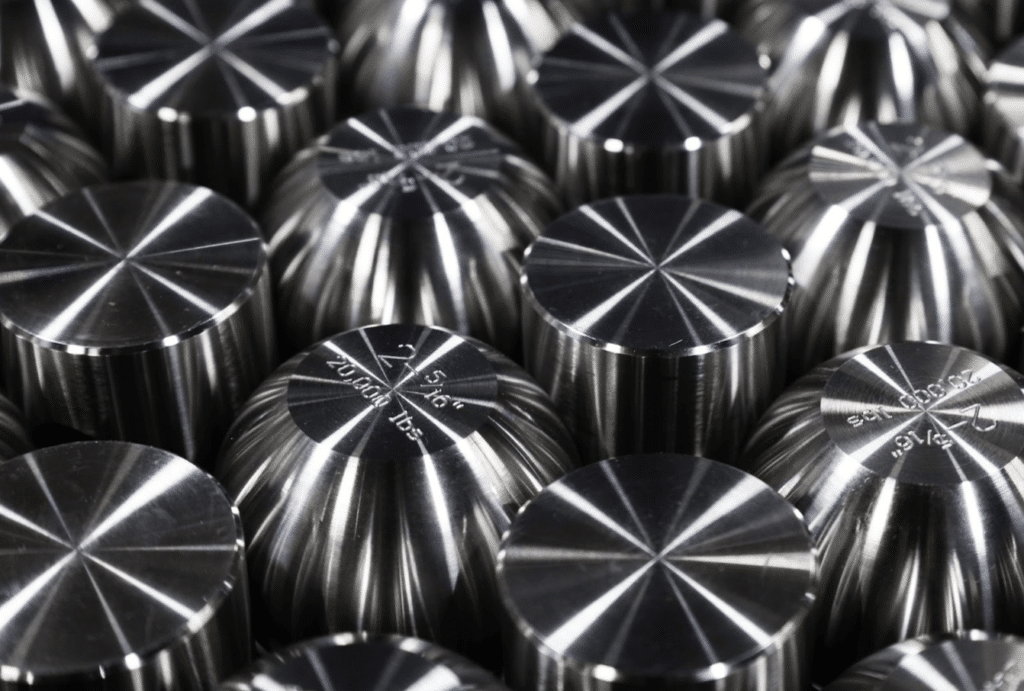

Headquartered in Lindon, Utah, Weigh Safe combines the skills of USA and global experts in mechanical, manufacturing, and electrical engineering with precision hands-on design and machining. Our product development team continually innovates across all towing categories, delivering new and improved towing accessories that are machined to the tightest tolerances from aircraft-grade aluminum, stainless steel, and other high-quality materials.

With a unified and dedicated manufacturing team, rigorous inspection processes, and comprehensive quality control, Weigh Safe ensures that each product meets or exceeds industry standards, providing our customers with the safety, reliability, and performance they deserve.

With over two decades of experience in precision machining for the towing industry, Weigh Safe has established itself as a leader in safety and performance. Our expertise spans intricate programming, innovative fixturing solutions, and exceptional proficiency in milling and turning. We take pride in crafting high-precision towing components, developing robust hitch systems, and producing custom towing accessories that set the standard for quality and durability. As the only trailer hitch manufacturer in the United States with patented technology that has revolutionized the industry, we’ve redefined what it means to offer true “Towing Peace of Mind.”

Engineering Process

product development

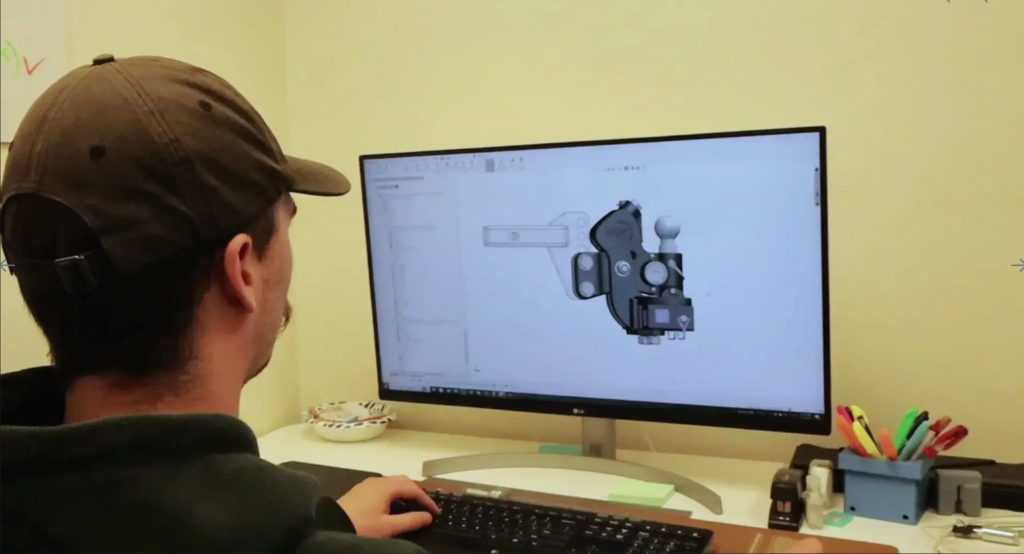

Our product development process is meticulously crafted and proprietary, designed to ensure that every idea undergoes rigorous evaluation to meet the highest industry standards. We carefully scrutinize every aspect of product requirements, leaving no detail unattended. This thorough approach guarantees that each product we bring to market not only meets our stringent quality benchmarks but also delivers outstanding performance for our customers.

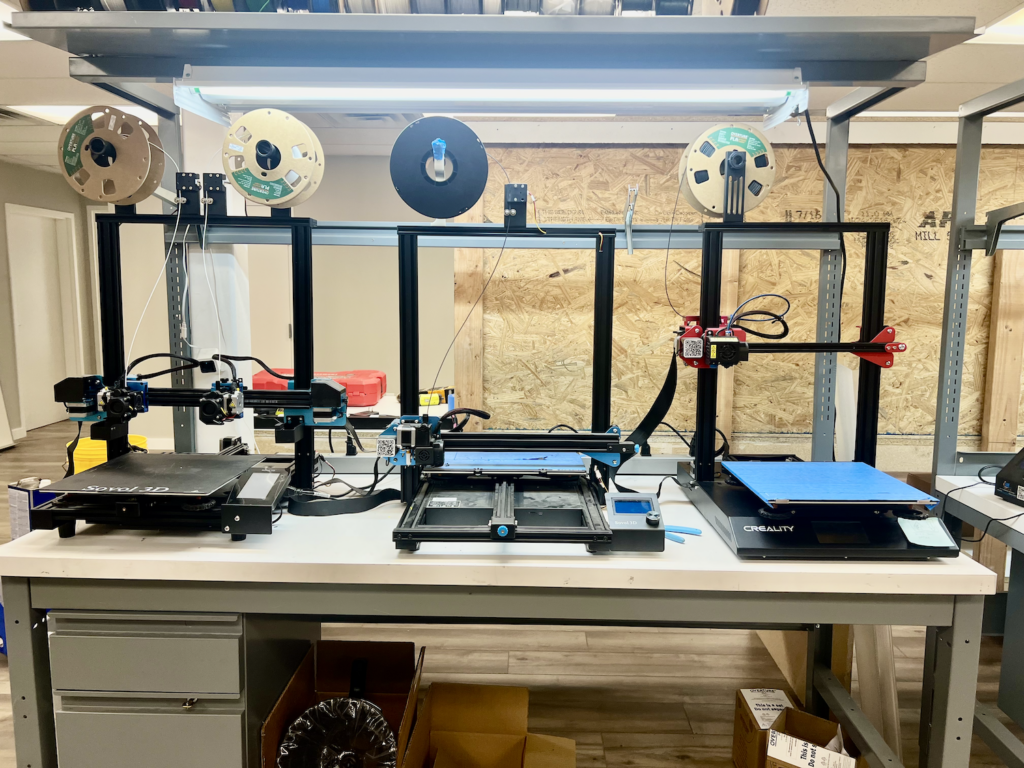

REsources

We leverage state-of-the-art engineering tools and resources, including industry-leading CAD, Simulation/FEA, and CAM software. Our in-house laboratory is equipped with a custom hydraulic force stand, allowing us to rigorously test each product to ensure it not only meets but exceeds industry standards. By applying extreme forces and conducting comprehensive fatigue testing, we verify the strength and durability of every product. Our rapid prototyping capabilities, supported by advanced 3D printers, mills, and lathes, enable us to quickly transform innovative concepts into reality, pushing the boundaries of what’s possible in the towing industry.

people

Our engineering team embodies a relentless passion for innovation, diligence, and an unwavering commitment to excellence. We take pride in recruiting only the most skilled and talented professionals, whose expertise is crucial in advancing Weigh Safe’s products to unprecedented levels of performance. With their boundless enthusiasm and deep technical knowledge, our engineers continually push the boundaries of what’s possible, setting new standards for engineering excellence in the towing industry.

Manufacturing

At Weigh Safe, our manufacturing ethos is built on a foundation of innovation, precision, and unwavering commitment to quality. We harness the power of advanced global manufacturing techniques—including forging, machining, and stringent material testing—to craft towing products that set the industry standard for strength and durability. Our dedication to precision is evident at every stage, from initial product design, where each concept is meticulously refined, to the final inspections before packaging and shipment, ensuring that every product that reaches our customers is flawless.

We believe that true quality begins with the materials we choose and the processes we perfect. By integrating cutting-edge tools, such as 4-axis mills and custom hydraulic force stands, into our production, we maintain exceptionally high tolerances and guarantee that each product is built to last. Our commitment to keeping all manufacturing processes closely integrated allows us to improve quality, streamline testing, and efficiently manage production, enabling us to meet customer demands quickly while keeping costs low.

Above all, we are driven by a passion for excellence and a deep respect for our customers. We strive to deliver products that not only meet but exceed expectations, offering “Towing Peace of Mind” with every hitch we create. Our manufacturing ethos is not just about making products; it’s about crafting solutions that enhance safety, performance, and the towing experience for everyone who trusts Weigh Safe.

Process

Our global manufacturing process is designed to produce the highest quality towing products by integrating a wide range of advanced techniques, including bending, cutting, powder coating, machining, forging, and casting. We place a strong emphasis on forging steel and aluminum, which enhances the strength and durability of our products, ensuring they last longer and perform better. Throughout the manufacturing process, we use go/no-go gauges at every step to verify precision, maintaining exceptionally high tolerances, especially during machining on our 4-axis mills. This approach not only enables us to produce products faster, meeting customer demand with greater responsiveness, but also allows us to leverage global expertise to continually refine our processes, delivering a superior end product while keeping costs low for our customers.

quality control

We conduct stringent material testing, including tensile and chemistry tests, both before and after production, to guarantee that all materials meet our rigorous standards. By keeping all manufacturing processes closely integrated, we improve quality, streamline testing and fitment, and efficiently manage production. Our commitment to quality control extends into the product design phase, where each concept undergoes meticulous scrutiny to ensure it meets our high standards from the very beginning. Before packaging and shipment, every product is thoroughly inspected, ensuring that our customers receive only the best.