Any of you who own a trailer understand the antsy feeling to get out and use it whether that be a weekend camping trip, or to work on a project. But these memorable experiences can quickly turn sour when your trailer malfunctions.

In this article, we will take you through the process to best reduce common issues when it comes to maintenance, so that your trailer doesn’t bust your plans.

Why Trailer Maintenance Is Important for Towing Safety

Maintaining trailers is an oft-forgotten chore, but a vitally important one if you want to keep your towing experience safe and sound. Without regular upkeep, trailers can become corroded or break down due to wear-and-tear, leaving you stranded in the middle of nowhere. To avoid this misery, it is vital that you keep up on maintenance.

Not only is trailer maintenance important for towing safety, but it’s also required by law in many states. Properly maintaining your trailer is a crucial part of being a responsible trailer owner and operator.

How Often Should You Perform Trailer Maintenance

The frequency of your trailer maintenance will depend on how often you use your trailer and the type of trailer you have. Generally speaking, it’s a good idea to do your own inspection for your trailer before each trip. This way, you can catch any problems early and prevent them from becoming bigger issues down the road. Regardless of how often you use your trailer, it is suggested and often required by law to have a trailer inspection done every 12 months by a qualified inspector.

Important Tip: Check your trailer’s owner’s manual for specific maintenance recommendations. The manual will have the most accurate information about your trailer and what it needs to stay in good condition. You should also be aware of your states regulations and laws regarding the matter.

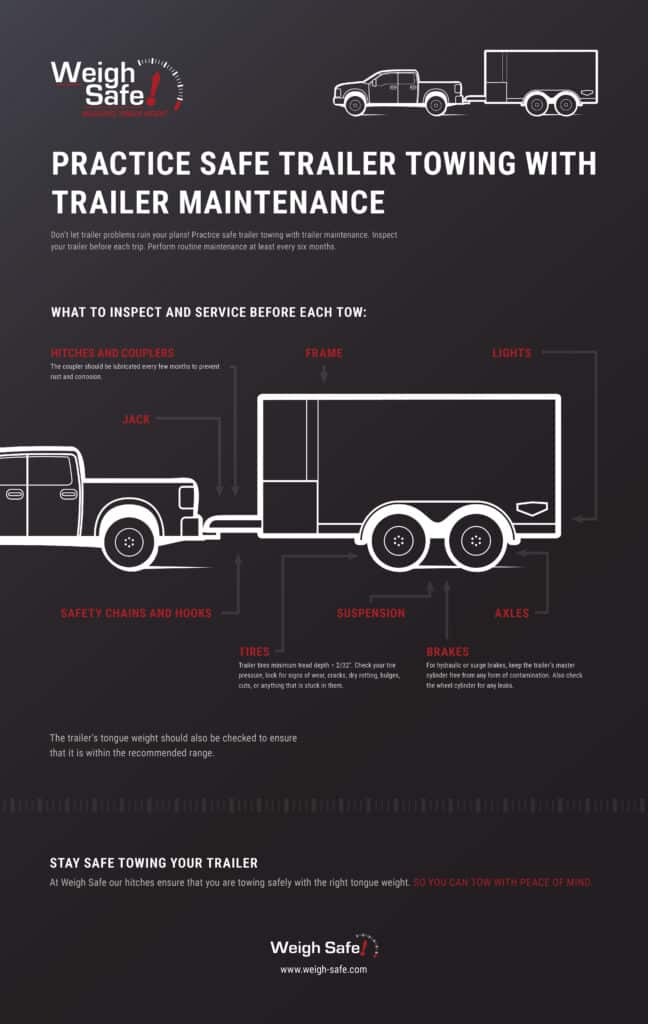

What to Inspect and Service Before Each Tow

Here are the maintenance tasks that you should always perform before each towing trip:

axles

You can maintain your trailer by ensuring that the axles are correctly aligned. An unaligned trailer axle can cause uneven tire wear, strain on the suspension, and potentially increase trailer sway. Next, check all the axle welds and joints for any cracks or damage.

Additionally, the trailer axles should be greased at least once per season. If the trailer is used frequently or for heavy-duty purposes, the axles may need to be greased more often.

When greasing the trailer axles, be sure to use high-quality grease that is designed for trailer use. This will help to prevent corrosion and keep the axles operating smoothly.

brakes

The brakes must function properly for safe trailer towing. Before each tow, check the trailer brakes to make sure they are in good condition. To do this, engage the trailer’s emergency brake and then try to push the trailer forward. The trailer should not move when the emergency brake is engaged.

If you notice any problems with the trailer brakes, have them serviced by a qualified technician as soon as possible. Only attempt to repair trailer brakes yourself if you are qualified to do so.

It is also important to check the trailer’s brake fluid, which should be flushed and replaced every two years.

Electric Brakes

If the trailer has electric brakes, you should also test the trailer’s breakaway system. The breakaway system is designed to engage the trailer brakes if the trailer becomes disconnected from the tow vehicle. Test the breakaway system by pulling on the trailer’s breakaway switch and then trying to push the trailer forward. A functioning breakaway system should keep the trailer in place when the switch is engaged.

Hydraulic/Surge Brakes

Maintaining the optimal condition of your trailer’s hydraulic or surge brakes is vital for ensuring a safe and efficient journey. Before each trip, it is essential to inspect the trailer’s master cylinder for any form of contamination, as well as keeping the brake fluid reservoir located close to the axle filled to its recommended level.

tires

Tire tread is often overlooked, but is one of the essential contributing factors to having a safe trip. In the United States, the legal minimum for tread depth is 2/32″. Tires are also required to have wear bars that are visible when the tread depth has been reached. Wear bars must also be replaced when they are worn down. If the trailer tires have cracks or dry rotting, the tires will need to be replaced regardless of the tread depth.

Before towing a trailer, it’s essential that the tires are properly inflated. Adequately inflated tires will allow for a smoother ride and will also prolong their life expectancy. But, don’t go overboard… Over-inflation of the tires can lead to blowouts, as the air pressure exerted on them is much higher than what they were designed to handle.

Check your tires for bulges, cuts, or anything that is stuck in them that shouldn’t be there.

It is also recommended to keep a spare tire on board in the case that you get a flat tire. Be sure to check the spare tire periodically to make sure it is properly inflated and in good condition.

Lights

Lights may be the most overlooked item on the tow checklist. Checking to see if all the trailer lights work includes the brake lights, turn signals, and marker lights. Without working lights, an accident is prone to happen as the vehicles on the road will be unable to see the trailer merging lanes in certain circumstances.

The simplest way to check that the trailer lights are working is to have someone stand behind the trailer while another person operates turn signals, reversing the trailer and braking.

Another area to check in your inspection is the connectors, be sure to check for any rust or corrosion. If you are towing an electric trailer, make sure that the connector on both the trailer and the tow vehicle are wired the same.

Check Out Our Products!

suspension

The trailer suspension is the system that supports the trailer and its load. It helps to absorb the impact of bumps and potholes, which can damage the trailer and its contents.

To test the trailer suspension, push down on the trailer and then let go. The trailer should bounce back up and then settle back into place. If the trailer does not bounce back up, the shocks may need to be replaced.

Another thing to note is whether you are having consistent trailer sway to any degree, the trailer’s suspension may need to be adjusted. Sway can also be caused by improper loading of the trailer. Be sure to evenly distribute the weight in the trailer so that it is not heavier on one side than the other.

Safety Chains and Hooks

The safety chains and hooks on a trailer are needed for keeping the trailer attached to the tow vehicle in case of a hitch failure. Check for any wear and tear on the trailer’s safety chains and hooks. Pay very close attention to chains that may have been dragging on the road.

Jack

The trailer jack should be able to lift the trailer off the ground with ease. Try testing the trailer jack by first lowering the trailer onto its stabilizer jacks. Then try to raise the trailer back up using the trailer jack. If the trailer jack fails the test, you’ll need to get a replacement.

Frame

Check for any signs of rust or damage on the frame and all its elements including all fasteners, screws, and bolts. If the trailer has a steel frame, it should be treated with a rust-resistant coating to prevent further corrosion. If the trailer has an aluminum frame, it should be inspected for signs of denting or other damage. Aluminum frames are susceptible to damage from road debris and rocks.

Hitches and Couplers

The hitches and couplers help the trailer stay connected to the car. You don’t want your trailer to come detached while you’re driving!

The trailer hitch and coupler should be inspected for damage before each trip. The hitch should be securely connected to the trailer, and the coupler should be properly locked. The coupler should be lubricated every few months to prevent rust and corrosion.

The trailer’s tongue weight should also be checked to ensure that it is within the recommended range. Our Weigh Safe weight distribution hitch can make it easy for you to measure the tongue weight of your towing load.

Let's Sum it Up:

Stay Safe This Season With Weigh Safe

Maintenance is key to keeping your trailer in good condition and safe on the road. Be sure to check all the components of your trailer before each trip, and perform any necessary maintenance tasks to keep your trailer in good shape. By taking care of your trailer, you can help reduce accidents and promote safety on the road for everyone.

The top priority at Weigh Safe is the safety for everyone on the road. Our hitches ensure that you are towing safely with adequate tongue weight. If you want to tow with peace of mind, check out our products today!

Shop now